Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-08

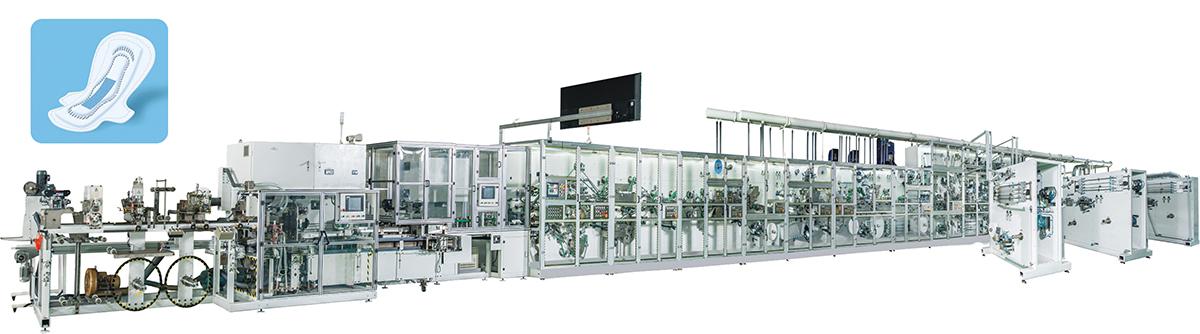

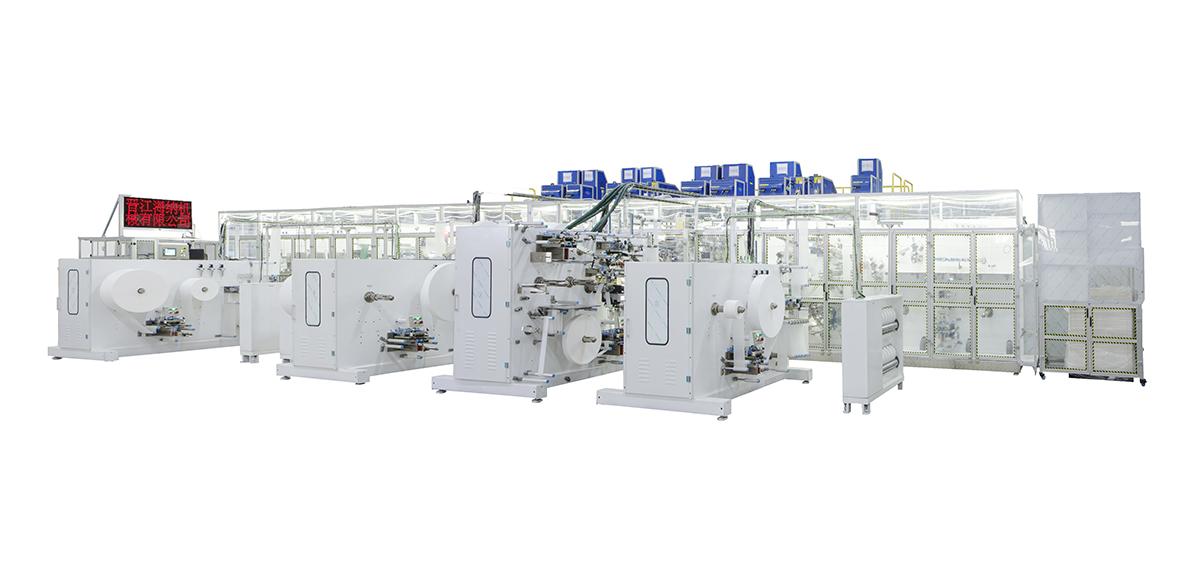

In the use of diaper manufacturing equipment, corresponding maintenance and management should be taken according to the working conditions of the equipment. At the same time, operators should also understand the standards and items of machine maintenance, maintain and manage them in strict accordance with the use requirements, and timely monitor the working environment of infant diaper manufacturing machine in the process of use.

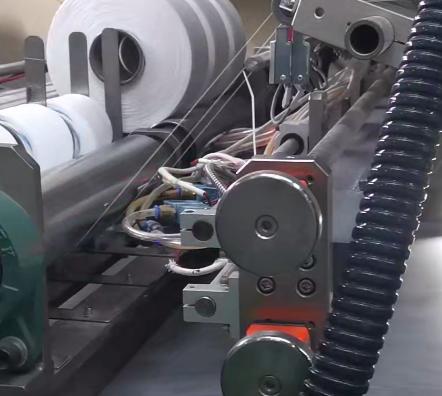

The maintenance and repair of diaper manufacturing equipment is a maintenance strategy based on prevention and supplemented by repair. In the process of using mechanical equipment, maintenance is used to increase the service life of the equipment and prevent failures. Through the operator's inspection of the equipment before work, supervision of the operation of the equipment during work, cleaning and maintenance after work, it can maintain the normal working state of the equipment, maintain the equipment from failure or prolong the service time of the equipment.

In fact, the knowledge level and business ability of operators determine the use of diaper manufacturing equipment. A mechanical equipment operator should adapt to the development requirements of the times, keep pace with the times and improve his professional level. Mechanical equipment, especially automated mechanical equipment, involves a wide range of knowledge. Enterprises should carry out regular or irregular training for mechanical equipment operators according to the requirements of their jobs, so as to improve their ability to adapt to the development of science and technology.

diaper manufacturing equipment must be operated in strict accordance with the specification requirements in the process of use, otherwise there may be potential safety hazards in the operation of mechanical equipment. Therefore, as an operator, he should be familiar with the operation process of mechanical equipment, carry out production in strict accordance with the operation requirements, and do a good job in eliminating potential safety hazards. In the process of work, he can effectively control the running state of the equipment, give full play to the functions of the equipment and carry out safe production to the end.

In addition, if enterprises want to further expand production and continuously improve their own economic benefits, it is necessary to carry out corresponding transformation and upgrading of diaper manufacturing equipment. Therefore, this requires enterprises to do a good job in the technical transformation of mechanical equipment in the process of daily management, and effectively implement the maintenance and management of mechanical equipment, so as to make the diaper manufacturing machine run long-term, stable and effective in a real sense.