Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-08

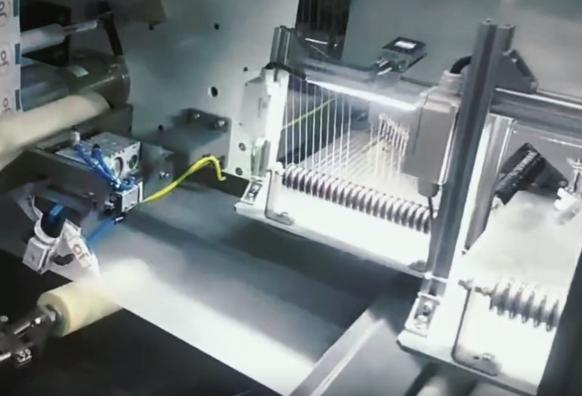

With the continuous development of science, the performance of mini sanitary pad making machine will be gradually updated and improved. How to correctly master its performance and the management of installation and commissioning in actual operation also requires staff to continuously accumulate experience in work, master the principle of installation and commissioning, and be prepared to judge and eliminate the faults existing in mechanical equipment, so as to ensure the normal operation of mechanical equipment. Many people don't know much about mechanical equipment. Next, I will introduce the installation process and requirements of sanitary pads making machine.

The construction organization design and the selection of equipment and facilities of mini sanitary pad making machine are jointly studied and agreed by relevant scientific and technological personnel. Through technical calculation and checking calculation, it not only has its use value, but also ensures good economic benefits. Do not change the selected equipment casually, otherwise it will affect the progress of basic work.

Every installation sequence of mini sanitary pad making machine is scientific. The planned queue of an installation project is discharged through various considerations and technical demonstration, which is scientifically based and instructive Don't change it casually. In order to avoid causing work slowdown and the continuous progress of the project. For large-scale installation projects, due to the large number of equipment and installation links, there must be a general arrangement for each installation to achieve unified arrangement. There must be a mechanical team leader (or deputy project manager) with unified command in the construction team to coordinate and deal with various works, brainstorm and solicit more work opinions from employees.

The installation of every Mini sanitary pad making machine has strict technical requirements. Only by constructing according to the design technical requirements, can we reduce unnecessary time loss and material consumption. The foundation of a kind of equipment is calculated and designed by the design department. Only when it is constructed according to the requirements can the quality and safety be guaranteed.

When installing the mini sanitary pad making machine, the machinist must undergo pre job training, master general installation knowledge, and be familiar with installation standards. Those who need to be leveled must be leveled. There must be more than one bolt at the connection position and more than one bolt at the position where the anchor bolt should be threaded; Electricians should connect the power supply and distribution of the equipment according to the regulations and specifications. The switches and control panels of the power supply equipment should be overhauled in advance. After the power is connected, the pad making machine must be commissioned.