Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-11

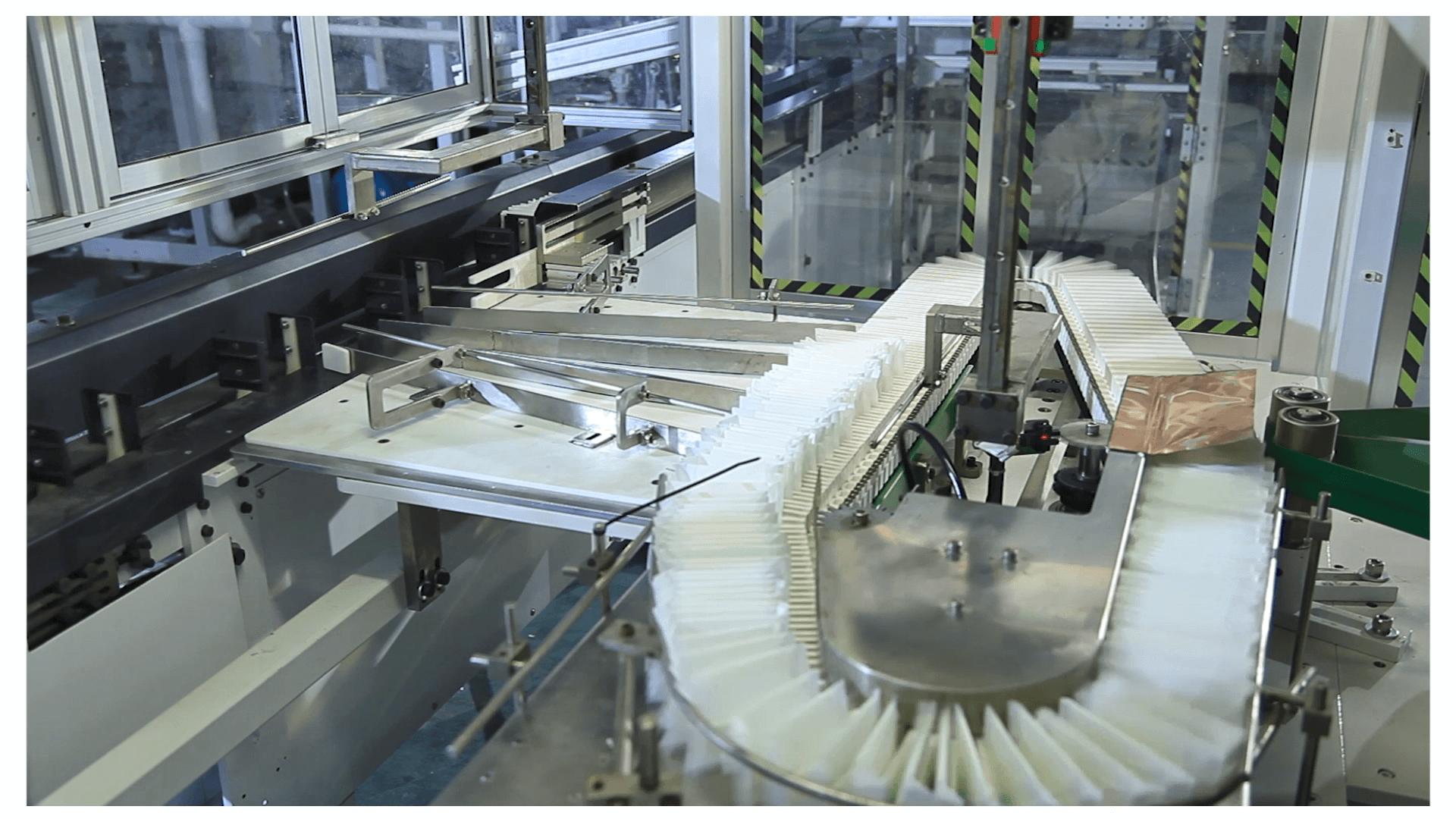

Baby diaper making production line is the main equipment of production. It keeps the machinery in good technical condition and gives full play to the best efficiency of the machinery, which plays a key role in completing the production task on time. Any machine and any part have a certain maintenance cycle and a certain service life. Correct use and standardized maintenance are effective methods and ways to reduce parts damage, prolong the service life of machinery and improve economic benefits. According to the structural characteristics and working principle of the machine, combined with working practice, this paper briefly introduces the use methods and maintenance measures of infant diaper production line.

The specific contents and requirements of daily maintenance and regular maintenance of the equipment have been put forward when the baby diaper making production line leaves the factory. However, in the maintenance work, people often only do qualitative maintenance, rather than quantitative maintenance according to the maintenance items and requirements. Even if it is done, there is no corresponding maintenance record.

During the technical maintenance of mechanical equipment, corresponding common tools and special tools are also required. All kinds of tools must be complete and recorded. At the same time, according to the different environmental conditions of each construction site, the workbench, car trough, workshop and other facilities required for maintenance and repair shall be set to ensure that the technical inspection and maintenance of various machinery can be carried out smoothly, and the preventive measures and necessary repairs shall be formulated according to the situation mastered in the process of inspection and maintenance, so as to ensure the intact technical state of the equipment.

In the long-term production process, due to the wear and corrosion of parts, the reduction or deterioration of lubricating oil, the loosening or displacement of fasteners and other reasons, the power, economy, safety and reliability of the machinery are reduced, and even failure and damage are caused, so that the whole machinery loses its working capacity. According to the change law of technical conditions, before the parts have reached the limit wear or failure, take corresponding preventive measures to reduce the wear speed of parts, eliminate the hidden dangers of failure, ensure the normal operation of machinery and prolong the service life, which is the maintenance of machinery.

Keep the baby diaper making production line in good condition and ready to start or run at any time; Under the condition of reasonable use, it will not stop due to midway damage; During use, it will not affect safety or driving due to mechanical accidents; Maintain the technical balance of all parts and components at the longest overhaul interval; To minimize the consumption of oil, tires and spare parts.

To sum up, the maintenance of baby diaper making production line is an effective means to restore mechanical properties and prolong service life. However, in the actual operation process, some users and maintenance personnel have many wrong practices, which affect the normal use of machinery.