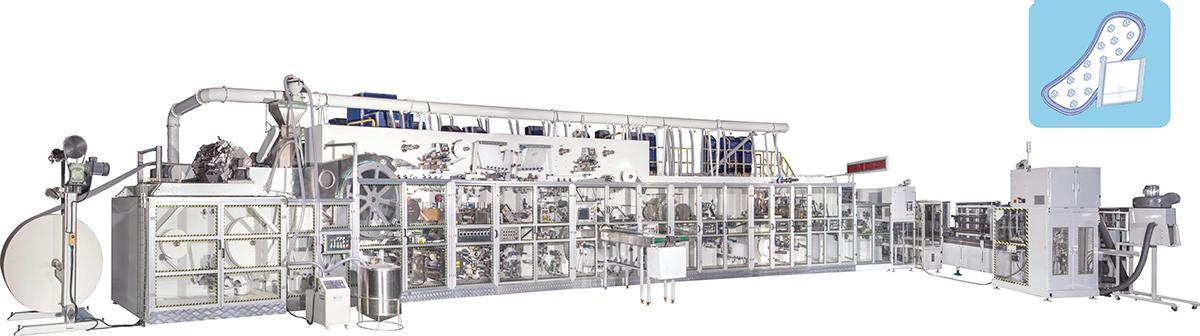

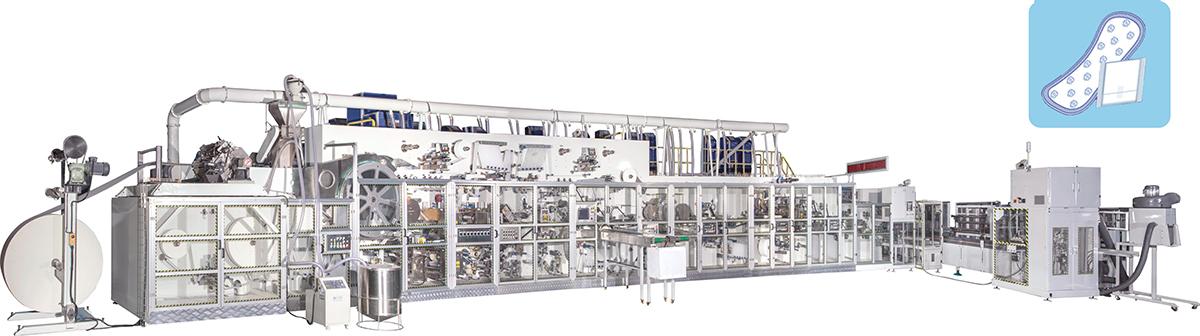

The sanitary napkin production machine is a modern and advanced technology designed for the manufacturing of high-quality sanitary napkins. The machine is a fully automated production line that ensures excellent performance, high efficiency, and cost-effectiveness.

It has several features such as auto tension control, auto web guiding system, and automatic counting and stacking, which make it suitable for mass production of sanitary napkins. The machine is easy to operate, and the finished products are of consistent quality.

It is designed with several units, such as the raw material feeding unit, the moulding unit, the sealing unit, and the folding unit. Therefore, the sanitary napkin production machine ensures maximum production output, and it is an ideal investment for manufacturers who want to produce high-quality sanitary napkins in bulk. It guarantees a high degree of hygiene and the comfort that every woman deserves during their menstrual cycle.

Best sanitary pad machine+Auto Bagger

|

Dimensions(L×W×H8) |

31m*4m*5m |

|

Design Speed: |

1200ppm |

|

Stable Working Speed: |

1000ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

50 tons |

Factors influencing the quality management of Best sanitary pad machine maintenance

Due to the long-term operation of the Best sanitary pad machine, it is inevitable that various failures will occur. Through mechanical maintenance, defects are repaired, functions are improved, and normal operation is ensured. Maintenance quality management plays a decisive role in the operation status and economic benefits of equipment after maintenance. It is necessary to strengthen the quality management during maintenance, improve the maintenance level, and ensure the integrity rate of the equipment.

FULL Auto Best sanitary pad machine+Auto Bagger

| No. | Raw materials |

| 1 | Topsheet NW |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | Backsheet |

| 5 | Back release paper |

| 6 | Pouch film |

| 7 | Easy tape |

| 8 | Airlaid paper |

| 9 | Construction glue |

| 10 | Position glue |

A sanitary napkin making machine is an essential device in the manufacturing industry that produces feminine hygiene products. It is a highly efficient and...

Fully automatic sanitary pad machine is a highly advanced machine that is solely designed for the production of sanitary pads. This machine is designed to ...

Overall size: 31mx4mx5m (for reference only). Product Structure: Flat(or textile edge)Topsheet,ADL(blue core), Tissue (or airlaid), Cotton core(mix with SA...

Our customers have noticed the difference in the quality of our feminine napkins since we started using this machine. Highly recommendedMegan H 2024-05-31

We've seen a significant increase in our production output since incorporating this Feminine Napkin Machine into our operations. It's a game-changer for usSarah L 2024-05-31

The Feminine Napkin Machine is a game-changer for our business. It's efficient, reliable, and produces high-quality products consistentlyRachel W 2024-05-31

Feminine Napkin Machine has saved us so much time and effort in producing feminine napkins. Couldn't be happier with our purchaseJennifer R 2024-05-31