Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-07-18

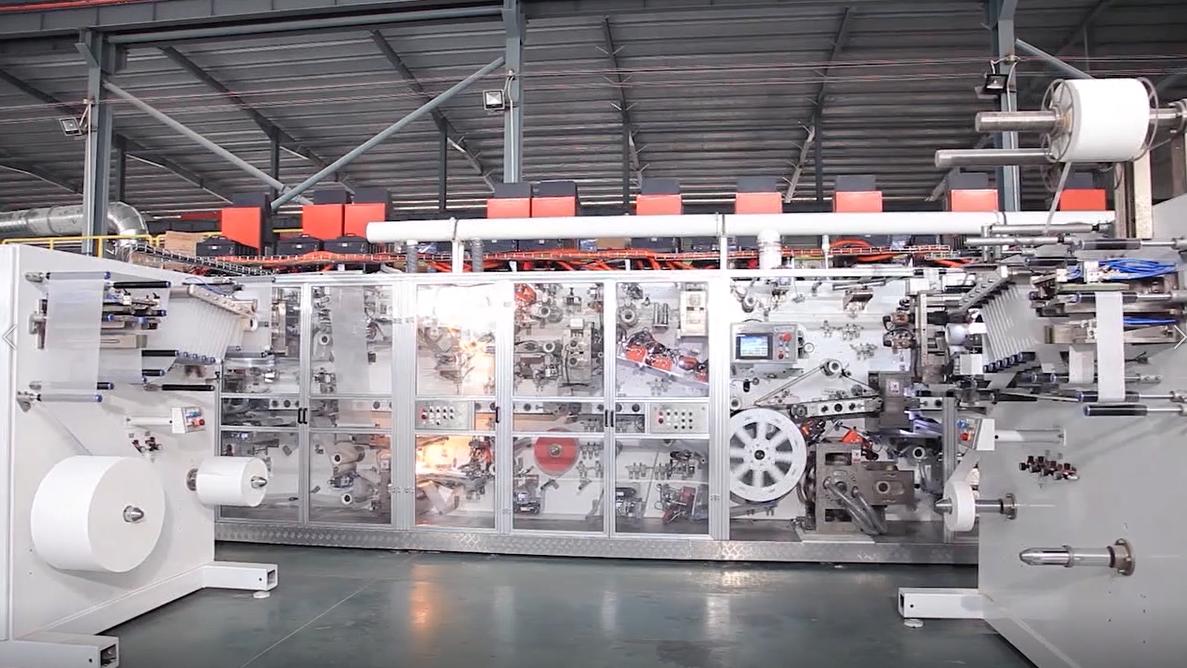

Pull up baby diaper machine is the product of mechatronics, with advanced technology and complex structure. The faults of machinery and equipment are also diverse and different. The causes of faults are generally complex, which brings many difficulties to the fault diagnosis and maintenance of machinery and equipment. Next, let's briefly introduce the fault classification and maintenance precautions of infant diaper machine.

pull up baby diaper machine mainly has several aspects.

(1) Systemic failure. This kind of failure refers to the failure of the machine system as long as certain conditions are met. For example, if the grid voltage is too high or too low, the system will generate an over voltage alarm or too low alarm; When the cutting amount is too large, overload alarm will be generated.

(2) Random failure. This kind of fault refers to the fault that only occasionally occurs once or twice under the same conditions. It is not easy to reproduce the same fault artificially, and sometimes it is difficult to encounter it again for a long time. It is difficult to analyze and diagnose this kind of fault. Generally, such faults are often related to the loosening and dislocation of mechanical structure, the drift of working characteristics of some components in the system and the decline of reliability of electrical components of the machine.

(3) Mechanical failure. This kind of fault mainly occurs in the main part of the machine, and can also be divided into mechanical component fault, hydraulic system fault, pneumatic system fault and lubrication system fault.

(4) Electrical failure. Electrical failure refers to the failure of electrical control system, mainly including the failure of device, PLC controller, servo unit, CRT display, power module, machine control element and detection switch. This part of the fault is a common fault of machinery and equipment, which should be paid enough attention.

For the maintenance and transformation of pull up baby diaper machine, some important contents should be well controlled.

(1) In machinery and equipment, the function of guide rail is no longer the same as that of traditional machines. In traditional machines, the guide rail only needs to meet the requirements of process and guidance accuracy, but in machinery and equipment, it is also required to have better wear resistance and greater strength, so as to prevent the deformation of guide rail from affecting the actual processing accuracy of machinery and equipment, and it should be well maintained and protected.

(2) For the electric control cabinet of machinery and equipment, although its internal components have reached the service life, its performance and parameters are still relatively stable. For some high-end imported machinery and equipment, the electric control cabinet does not need to be greatly disassembled and changed during the machine transformation. Secondly, in the selection of cables, it is necessary to select high-quality shielded cables, otherwise it will cause poor signal transmission, cause faults during equipment operation, and it is not easy to find.

(3) Transmission connection and screw rod accuracy will have a great impact on the accuracy of machinery and equipment. When selecting screw rod, its driving torque and machining accuracy should be considered. For ball screw, in practical application, its friction loss is relatively small, and the transmission efficiency is relatively high. It has good performance in terms of life and precision. Its starting torque is relatively close when it moves, which can effectively reduce the starting torque of the motor and meet the processing requirements of high-precision products.

This paper analyzes some problems encountered in the maintenance and transformation of pull up baby diaper machine, and puts forward some countermeasures. In the development of practical work, we need to control some common problems and work priorities, and better complete the transformation work by effectively avoiding problems, so as to realize the long-term and stable operation of machinery and equipment.