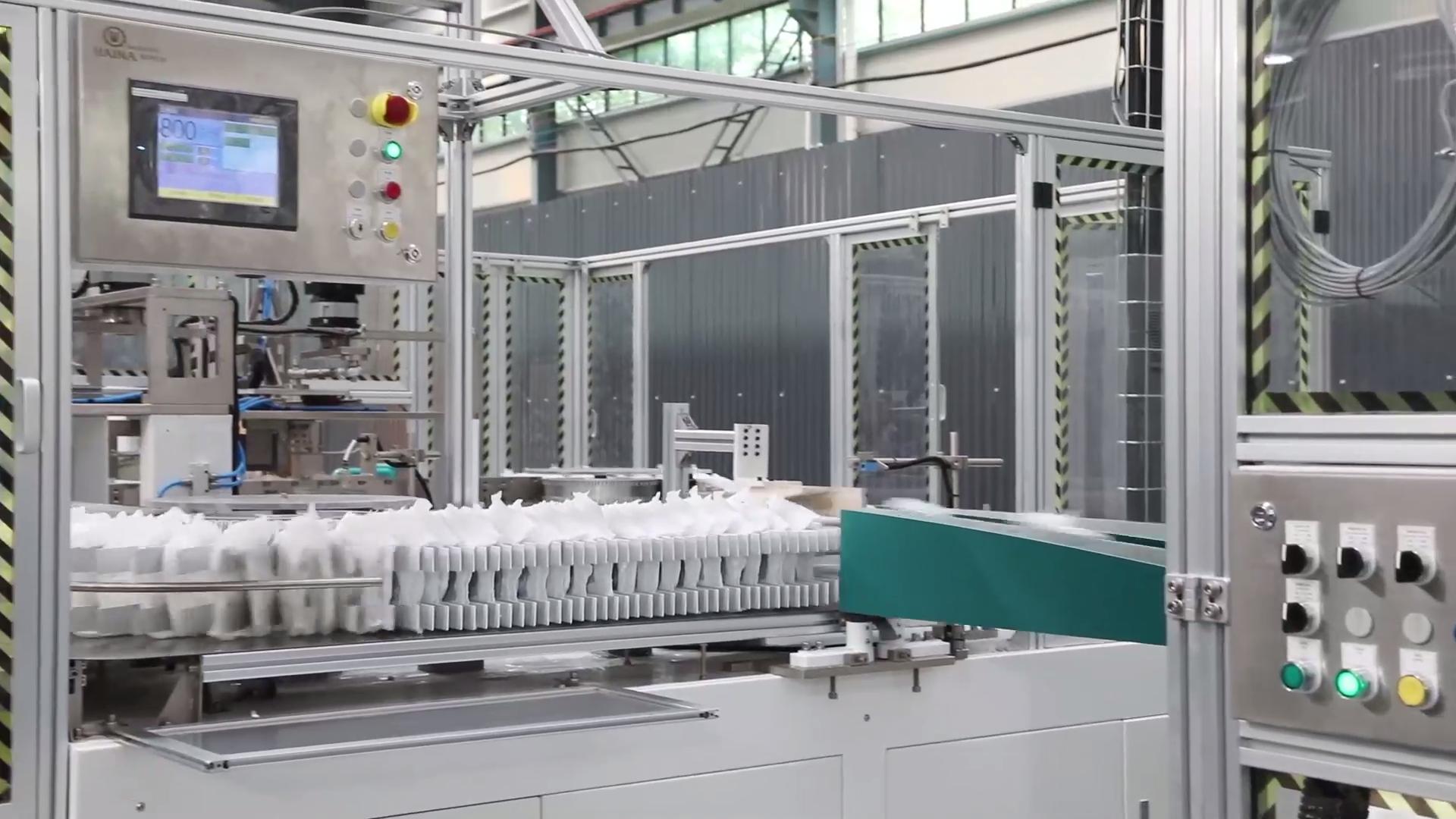

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

In the field of mechanical processing, because best sanitary pad machine has many advantages compared with traditional sanitary napkin machinery, it is widely used, but after failure, it is difficult to eliminate and maintain. In this way, the operator is required to pay attention to prevention when using best sanitary pad equipment, thereby reducing the probability of failure and improving the utilization rate of the equipment.

The machine should be placed in a relatively dust-free place with constant temperature and humidity. Although it is difficult to do at present, it is necessary to create the Heavenly Sword as much as possible, and try to get as close as possible to such a usage environment. In addition, in the case of normal use after the machine is installed, pay attention to the following. Before using the machine, checking the machine can reduce the failure of the machine during use and affect the production.

(1) Before powering on, check the appearance of the equipment, electrical pipelines and some external auxiliary equipment to see if there is any abnormality. Regular drainage of air compressors and air storage pressure vessels is required to prevent excessive moisture from accumulating and entering into the interior of the machine driven by airflow, causing corrosion and even damage to parts.

(2) Power on, according to the normal power-on sequence: the total power of the machine - the power of the equipment system - the power of the servo system - release the emergency stop button to reduce the impact on the electrical components of the equipment system and prolong the service life.

(3) After power-on, lubrication is an indispensable and important condition for any moving parts to maintain normal motion trajectory, reduce motion friction, and improve service life. This means that we must pay attention to check whether the amount of lubricating oil in the lubricating device is sufficient, replenish it in time when it is insufficient, and regularly check whether the liquid filter screen is blocked, check whether the oil circuit is unobstructed, and whether each oil outlet is normal with lubricating oil. outflow. Once such problems are discovered, they must be dealt with in a timely manner. If the moving parts such as machine rails and lead screws work without lubricating oil, on the one hand, it will increase the frictional resistance, increase the power consumption of the machine, and waste electric energy; on the other hand, it will accelerate the wear of the moving parts and affect the machine's performance Accuracy affects the quality of workpiece processing.

(1) When the machine is running, there will be a certain sound, but we should also pay attention to whether there is any abnormal sound, such as: the sound of the trachea bursting and leaking, the sound of the lubrication system changing suddenly, the cutting of the tool. "Squeak", etc., if such abnormal sounds occur, you must stop in time to prevent the situation from expanding.

(2) Touch the temperature of the machine. When the machine is running, it is normal for the temperature to rise to a certain extent, because there is friction during the operation process, which generates heat. Generally, when the machine runs for a certain period of time, it will reach The balance of heat, that is, the temperature is basically constant, generally at 50-60 degrees. If you put your hand on it and dare not stay, it means that the temperature is too high at this time, and you should check whether the lubrication is sufficient.

(3) Look at the parts where the working conditions of the machine are poor. Because the equipment and the machine are being processed, most of the time it is necessary to spray the coolant to rinse and cool the workpiece and the tool at one time, so that there are iron scraps and cutting fluid. The working conditions are very poor, especially the travel switch on the machine that moves back and forth on the tool holder is very likely to rush into the scraps of iron, making the contact retraction not flexible enough. At this time, we need to clean it up in time. In addition, during part of the cutting process, band-shaped iron filings may also be generated, which are easy to wrap around the tool and the workpiece, affecting the cooling effect and causing extrusion, causing damage to the tool, and it also needs to be cleaned in time.

(4) Smell the smell to see if there is any peculiar smell, mainly the pungent burnt smell of electrical pipelines.

Correct shutdown, timely cleaning, and daily maintenance. After the machine is used, it should be cleaned in time, and then apply oil on the surface of the moving guide rail and some parts of the machine for anti-rust maintenance.

The above are some of the problems that should be paid attention to in the process of using best sanitary pad machine. We should pay attention to it in the whole process, so as to give full play to the efficiency of the machine, improve the processing quality, and produce the expected benefits.