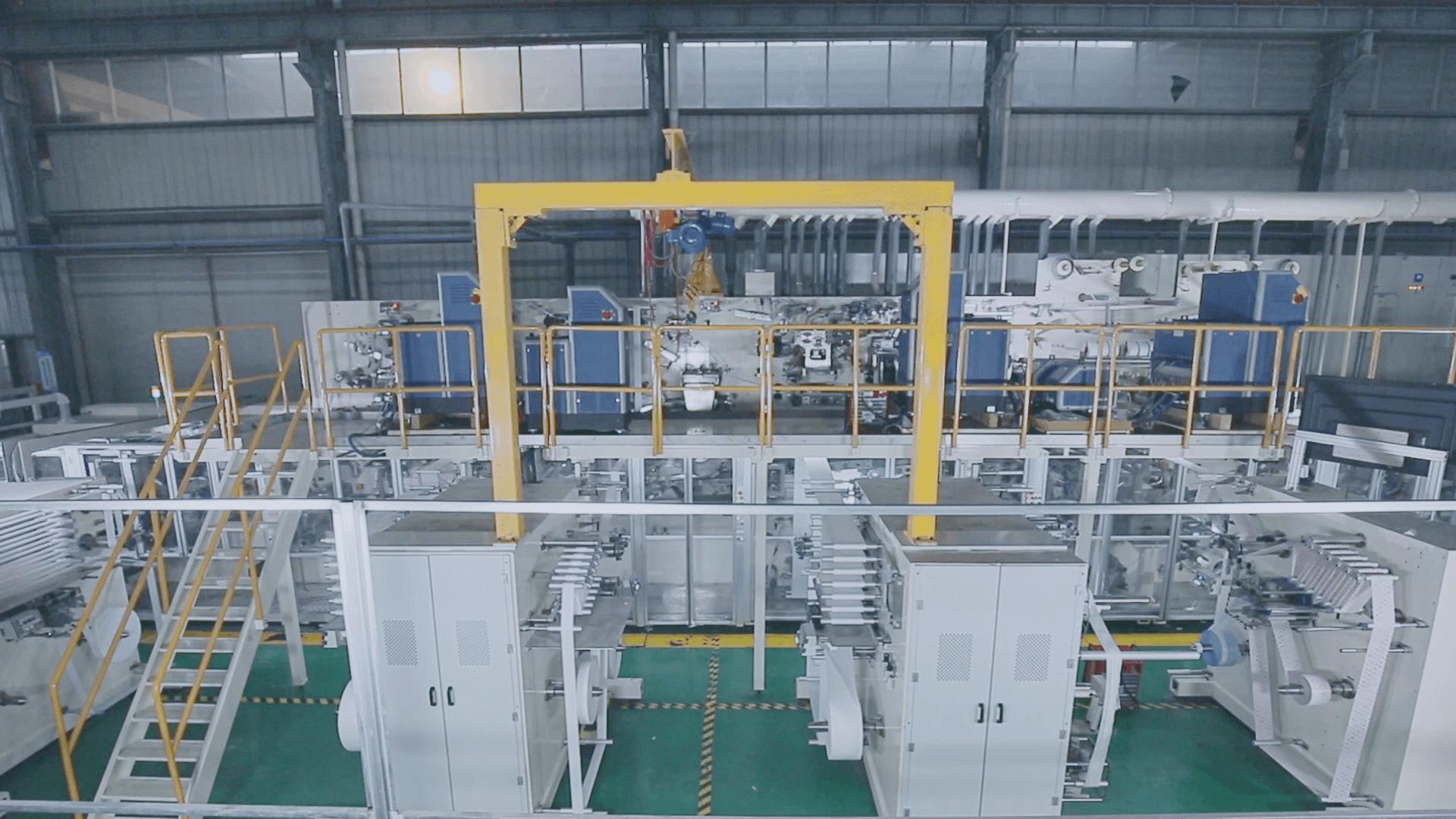

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

In daily work, infant diaper production line maintenance and repair personnel must not only have high-level technology, but also master relevant theoretical knowledge. Only the combination of theory and technology can better complete the operation. In the process of business operation, it is necessary to understand the importance of infant diaper making machine maintenance and overhaul, and establish a relevant management system, so as to achieve the purpose of stable development.

(1) In order to ensure that the infant diaper production line is always in a good technical state, it can be put into operation at any time, reduce downtime days, improve the mechanical integrity rate and utilization rate, reduce mechanical wear, extend the service life of the machinery, reduce the cost of mechanical operation and maintenance, and ensure safe production. , the maintenance of infant diaper making machine must be carried out.

(2) Mechanical maintenance must implement the principle of equal emphasis on maintenance and prevention, and achieve regular maintenance and mandatory maintenance, and correctly handle the relationship between use, maintenance and repair. It is not allowed to use only without maintenance and only repair without maintenance.

(3) Each team must do the maintenance work of various types of machinery according to the mechanical maintenance procedures and maintenance categories, and must not delay without reason. In special cases, the maintenance can be postponed after the approval of the special engineer in charge, but generally it should not exceed half of the specified maintenance interval. .

(4) The maintenance of machinery must ensure the quality, and carry out item by item according to the specified items and requirements, and must not miss or fail to guarantee. Maintenance items, maintenance quality and problems found in maintenance should be recorded and reported to the specialists in this department.

(5) Maintenance personnel and maintenance departments should achieve "three inspections and one handover (self-inspection, mutual inspection, full-time inspection and one-time handover qualification), and constantly summarize maintenance experience and improve maintenance quality.

(6) The Asset Management Department regularly supervises and inspects the mechanical maintenance of each unit, checks the quality of maintenance regularly or irregularly, and rewards the good and punishes the bad.

(1) infant diaper making equipment Maintenance Adhere to the promotion of the "cross" operation method with "cleaning, lubrication, adjustment, tightening, and anti-corrosion" as the main content, implement routine maintenance and regular maintenance, and strictly follow the cycle and inspection and maintenance items specified in the instruction manual. conduct.

(2) Routine maintenance is the cleaning and inspection carried out before, after and during the operation of the machine, mainly to check the condition of key and vulnerable parts, coolant, lubricant, fuel quantity, instrument indication, etc. Routine maintenance should be completed by the operator himself, and the "Mechanical Routine Maintenance Record" should be filled in carefully.

(3) First-level maintenance: generally carry out cleaning, tightening and lubricating operations, and partially carry out adjustment operations to maintain the technical condition of the machinery in good condition.

(4) Second-level maintenance: including all contents of first-level maintenance, centering on inspection and adjustment, to maintain good working performance of mechanical assemblies, mechanisms and parts. The asset manager of the user unit issues a notice and sends it to the operation team, mainly by the operator himself. Supervision.

(1) Seasonal maintenance: The main content is to replace the lubricating oil and fuel oil suitable for the season, take anti-freezing measures, and increase anti-freezing facilities. Organized and arranged by the user department, the operation squad leader inspects and supervises.

(2) Running-in period maintenance: After infant diaper making equipment, the running-in period maintenance must be carried out. The main contents are cleaning, tightening, adjustment and replacement of lubricating oil, which is completed by the user department, inspected by the asset manager, and supervised by the asset management department.

(3) Transfer maintenance: The transfer maintenance should be carried out before the machine is transferred to I. The content of the operation can be maintained according to the technical condition of the machine, and anti-corrosion can be carried out if necessary. The transfer and maintenance shall be arranged and implemented by the unit where the machinery is removed, inspected by the project department and the asset manager, and supervised by the asset management department.

(4) Parking and maintenance: The deactivated and sealed machinery should be maintained, mainly cleaning, anti-corrosion, moisture-proof, etc. The inventory machinery is entrusted by the asset management department for maintenance, and the machinery is maintained by the user department.

(5) After the maintenance plan is completed, it must be carefully inspected and accepted, and relevant materials should be compiled to ensure that the records are complete and factual.

Infant diaper production line. Maintenance and overhaul is an important way for enterprises to reduce operating costs, which fundamentally prolongs the service life of machinery and equipment and delays the replacement of old and new.