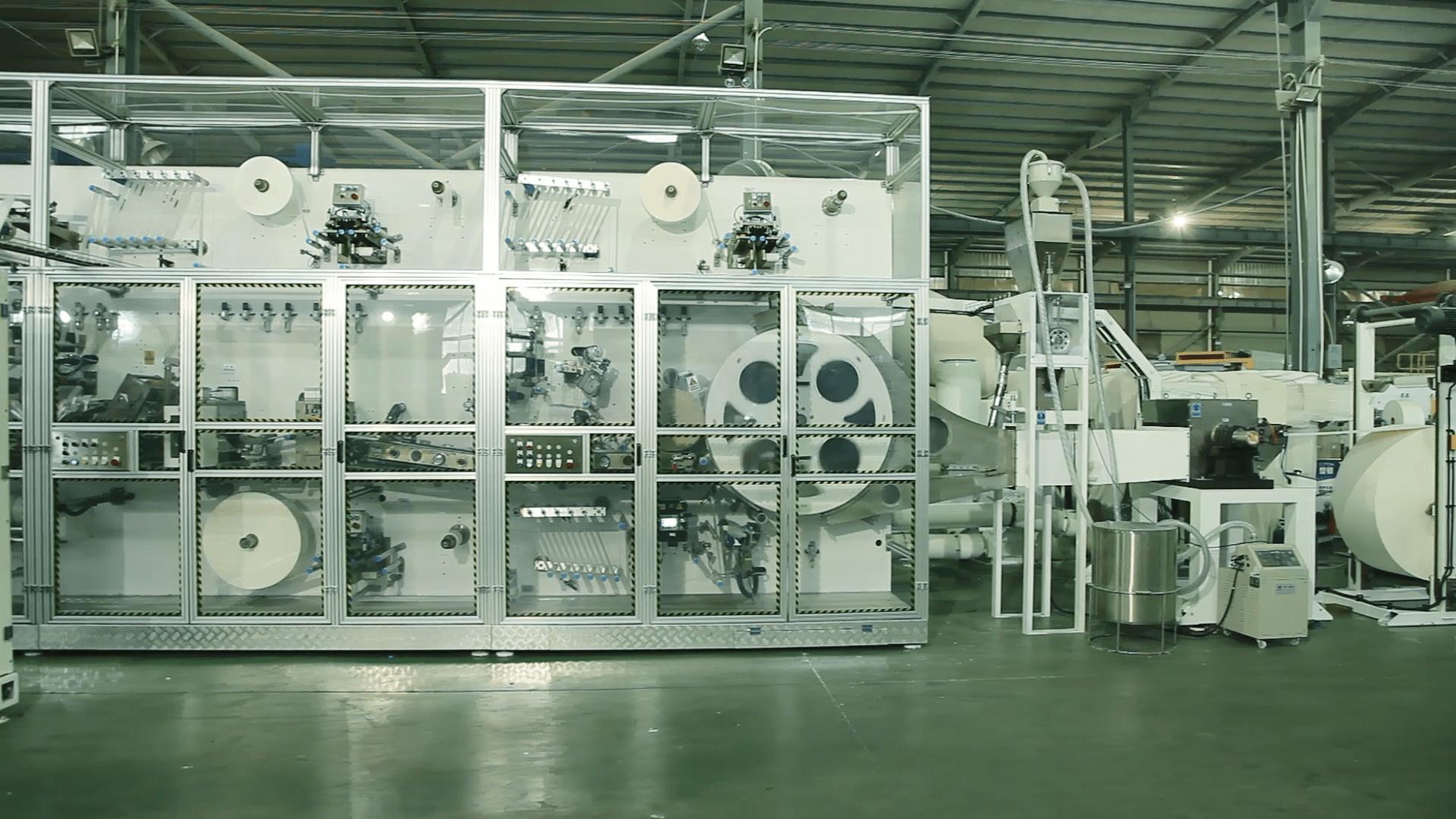

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

baby diaper making production line The three-level maintenance system is a mandatory maintenance system that focuses on the maintenance of the equipment and pays equal attention to the maintenance of the equipment. Mainly rely on the masses, give full play to the enthusiasm of the masses, implement group management and group repair, combine special groups with groups, and do a good job in baby diaper making equipment effective methods of maintenance.

baby diaper making production line The daily maintenance of equipment generally includes daily maintenance and weekly maintenance, also known as daily maintenance and weekly maintenance.

(1) Daily insurance

The daily maintenance is carried out by the equipment operators on duty, and the four things before the shift, the five attentions during the shift and the four things after the shift are conscientiously done.

Four things before the shift: digest the pattern data, check the shift record. Wipe baby diaper making equipment, lubricate and refuel as required. Check whether the handle position and manual operation part are correct and flexible, and whether the safety device is reliable. Run at low speed to check whether the transmission is normal, and whether the lubrication and cooling are smooth.

Class 5 Note: Pay attention to the sound of operation, whether the temperature, pressure, liquid level, electrical, hydraulic, and pneumatic systems of the equipment, instrument signals, and safety insurance are normal.

Four things after the shift: turn off the switch and put all handles to zero. Remove iron filings and dirt, wipe the oil on the rail surface and sliding surface of the equipment, and add oil. Clean the workplace, organize accessories, tools. Fill in the shift handover record and operating table time record, and go through the shift handover procedures.

(2) Weekly regular insurance

Weekly maintenance is carried out by equipment operators on weekends. The maintenance time is 2 hours for general equipment and 4 hours for fine, large and thin equipment.

Appearance: Clean the equipment guide rails, various transmission parts and exposed parts, and clean the workplace. To achieve clean inside and outside, no dead corners, no rust, clean surrounding environment.

Manipulation and transmission: Check the technical condition of each part, tighten the loose parts, and adjust the matching clearance. Check interlocks, safety devices. To achieve normal transmission sound, safe and reliable.

Hydraulic lubrication: clean the oil line, dust-proof felt, oil filter, add oil to the oil tank or change the oil. Check the hydraulic system to ensure that the oil is clean, the oil circuit is smooth, there is no leakage, and there is no abrasion.

Electrical system: Wipe the surface of the motor and the snakeskin tube, check the insulation and grounding, to achieve completeness, cleanliness and reliability.

The first-level maintenance is mainly based on operators, with the assistance of maintenance workers, dismantling and inspecting baby diaper making machine parts according to the plan, cleaning the specified parts, dredging the oil circuit and pipeline, replacing or cleaning the oil line, felt, oil filter, and adjusting the various parts of the equipment. the matching clearance, and fasten all parts of the equipment. The time required for the first-level maintenance is 4-8 hours. After the first-level maintenance is completed, a record should be made and the defects that have not been cleared should be noted. The workshop mechanic organizes the acceptance. The scope of the first guarantee should be all the equipment in use by the enterprise, and the key equipment should be strictly implemented. The main purpose of the first warranty is to reduce equipment wear, eliminate hidden dangers, extend the service life of the equipment, and provide equipment for the completion of the production tasks during the next first warranty period.

The second-level maintenance is mainly completed by maintenance workers and operators participating in it. The secondary maintenance is included in the maintenance plan of the equipment. Partial disassembly, inspection and repair of the equipment, replacement or repair of worn parts, cleaning, oil change, inspection and repair of electrical parts, so that the technical condition of the equipment can fully meet the requirements of the required equipment integrity standards. Secondary maintenance takes about 7 days.

After the completion of the two guarantees, the maintenance workers should fill in the maintenance records in detail, which will be accepted by the workshop mechanics and operators. The main purpose of the second guarantee is to make baby diaper making machine reach the integrity standard, improve and consolidate the equipment integrity rate, and extend the overhaul period.

To implement the "three-level maintenance system", the operators must make the equipment "three good", "four meetings", "four requirements" and abide by the "five disciplines". Due to the implementation of the three-level maintenance system, the integrity rate of baby diaper making production line has been effectively improved, the equipment accident rate has been reduced, the equipment overhaul cycle has been extended, and the equipment overhaul cost has been reduced, and good technical and economic effects have been achieved.