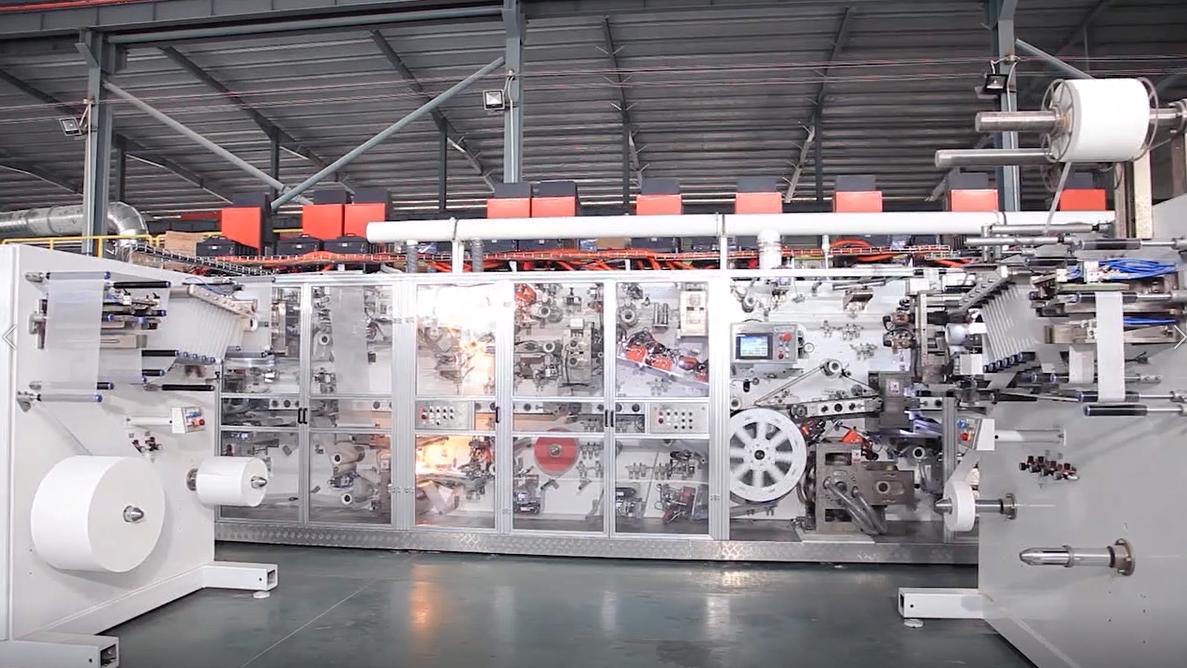

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-02-23

Preventive and regular maintenance are essential to the efficiency and life of female diaper production line. Early detection of problems can be repaired before the situation deteriorates. Regular inspection and analysis can be used to predict and prevent component failures that may cause safety hazards and machine failures. The following preventive maintenance measures can ensure the normal operation of female diaper making production line.

Train your maintenance personnel to systematically inspect the machine and related equipment according to the predetermined schedule. Depending on the type and scope of use of female diaper production line, it may need to be inspected annually, monthly, weekly or even daily. Priority should be given to machines that are extremely difficult to use, or machines that may cause serious accidents or production delays in the event of failure. Develop checklists for each piece of equipment so that inspections are efficient and consistent.

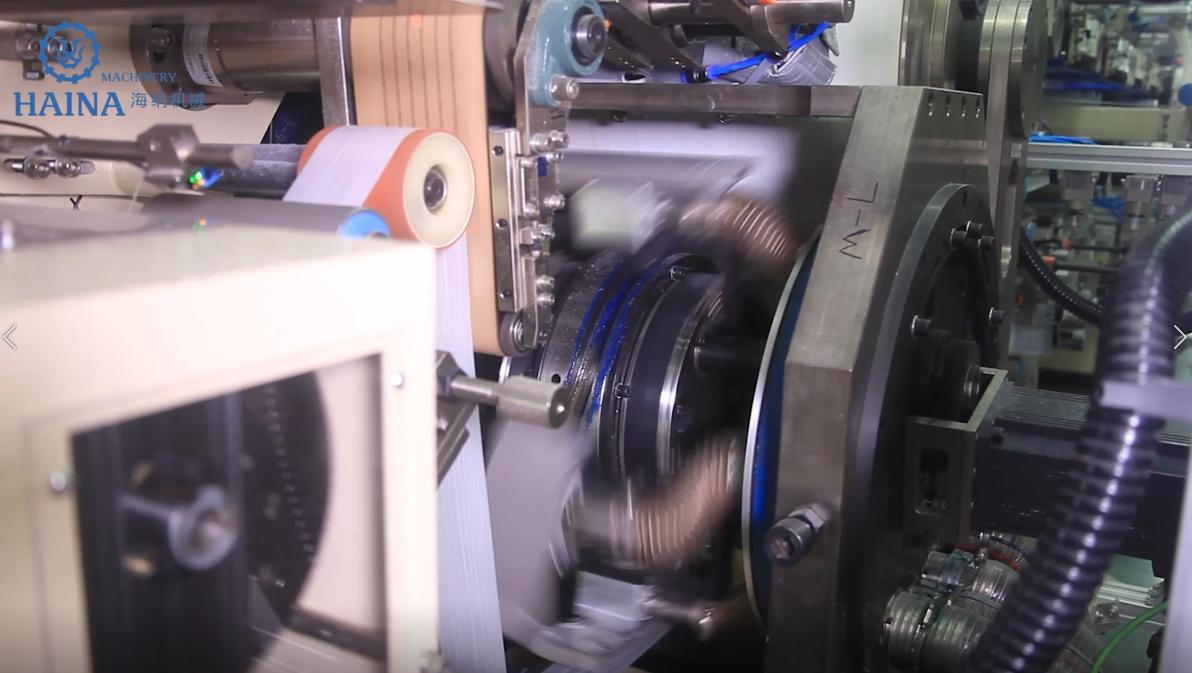

Establish a regular replacement plan for key or basic machine parts before the female diaper production line parts show signs of serious deterioration. In addition to the expected replacement schedule, prepare to repair or replace worn or defective components identified in routine inspection. Keep spare parts inventory so that corrective actions can be taken in time after inspection.

Checklists and inspection reports are valuable tools for improving your maintenance plan. Keep records of inspections, replacements and important findings, as well as a list of all female diaper production line data and specifications, so that you can determine service requirements, maintenance and part replacement plans.

Once the maintenance plan of your female diaper production line is established, please follow up with other procipline operators. Check whether it is carried out as planned, whether the report is being completed, whether the parts inventory is new, generally speaking, whether the program works and where it needs to be improved or adjusted. Regular evaluation of the plan will help to maintain the new state of the machine and show the continuous support of management.

Preventive maintenance and scheduled equipment overhaul can reduce the possibility of female diaper production line failure, thus reducing the risks faced by technicians during on-site maintenance, and significantly reducing accidents in the workplace.