Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-22

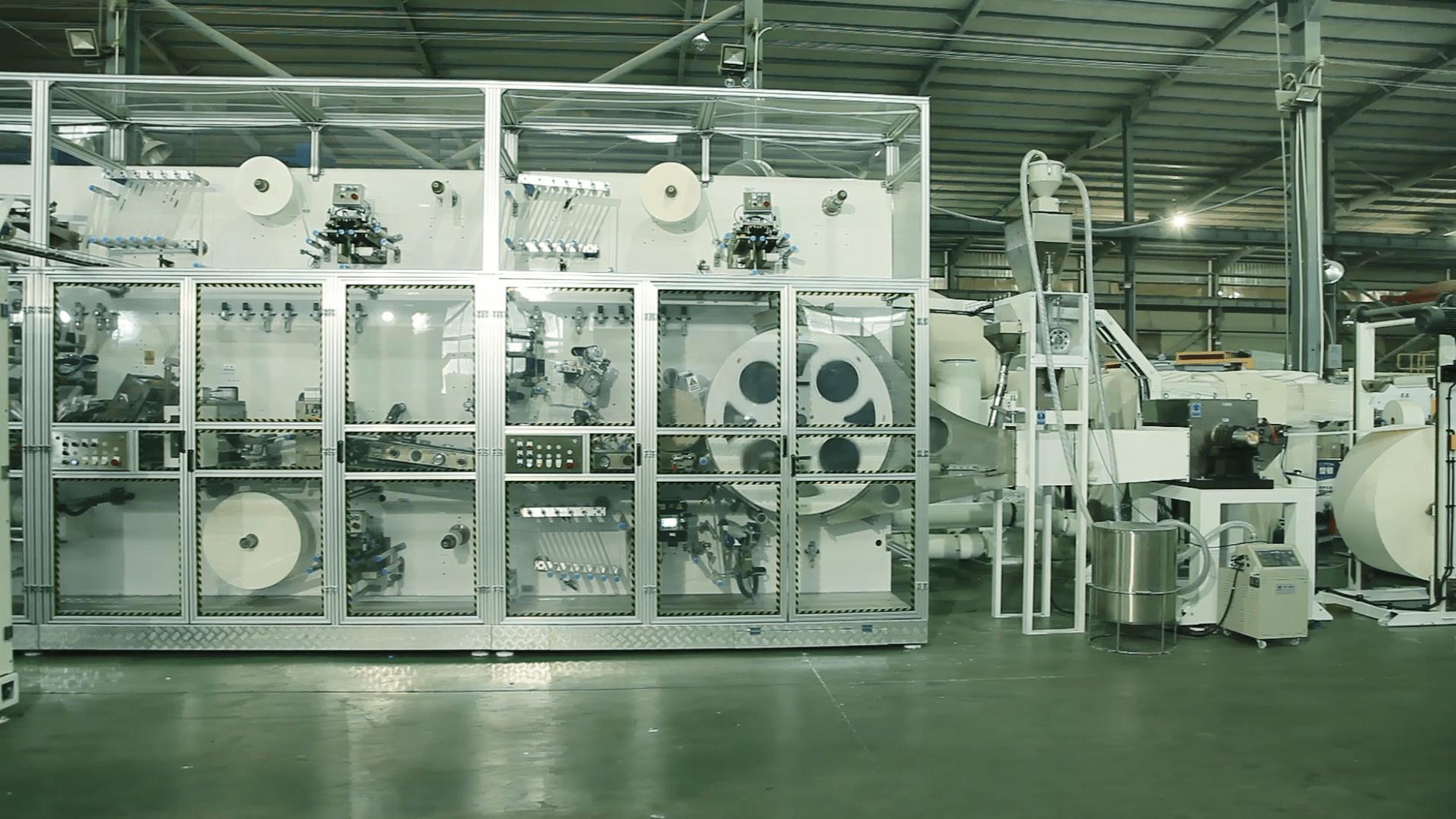

With the continuous progress of science and technology and the rapid development of modern production, the quality of mechanical equipment plays an increasingly obvious role as an important factor in determining the output, quality and cost of product production. In the course of use, pampers diaper machine will inevitably produce different degrees of wear, fatigue, deformation or damage. Over time, its technical state will gradually deteriorate, and its performance will also decrease. As an important part of equipment management, equipment maintenance is an important guarantee to prolong the service life, ensure the normal operation of production and prevent accidents. Compared with other methods, the following pampers diaper equipment main methods of maintenance are widely used.

As a preventive system, planned maintenance has been widely used in industrial enterprises since the 1950s, and has achieved good results in ensuring that machines are in good condition.

pampers diaper equipment There are several ways to plan maintenance:

(1) Standard maintenance method; this method is often used for equipment that must strictly ensure safe operation. This method makes specific plans in advance for the maintenance date, type and content of the equipment. Regardless of the technical state in operation, it is strictly implemented in accordance with the plan.

(2) Regular maintenance method; this method is to formulate the planned date of maintenance work and the approximate maintenance workload according to the usage of the equipment and the related maintenance cycle. The exact work arrangement will be specified in detail according to the preparations before each maintenance.

(3) Maintenance method after inspection; this Act only stipulates the inspection plan for equipment in advance, and determines the maintenance date and content based on the inspection results and previous maintenance materials.

On the one hand, the planned maintenance method can restore the working ability of the machine in a timely manner and prevent possible accidents; on the other hand, it can arrange its use and maintenance time in advance, and prepare the people, money, and materials needed for maintenance; Repair time can be shortened and maintenance quality improved.

Compared with traditional inspection, equipment diagnosis technology has developed from the sensory judgment of personnel to a large number of advanced scientific instruments and instruments, from manual testing to electronic instrument display, developed by senior technicians to scientifically convenient instruments and instruments, and general operators; from Downtime detection is a direct detection; the purpose of detection is to detect strain damage (wear, corrosion, etc.) to prevent failures from progressing to predict the natural life of the equipment. At present, this technology has developed into a systematic maintenance management method, which can monitor individual parts and main components of the entire set of equipment, and can also conduct comprehensive monitoring of the entire set of equipment.

Condition monitoring and maintenance is based on the information provided by the daily monitoring, regular inspection, condition monitoring and diagnosis of the equipment, through statistical analysis and processing, to determine its degree of deterioration, and to carry out appropriate repairs in a planned way before the failure occurs. Equipment status maintenance is the integrity rate and utilization rate of the public machine, which improves the quality of its maintenance work, saves various costs, and improves the overall benefit.

In the maintenance of equipment, there is also a method called after-the-fact maintenance method, or fault repair method, that is, if it is broken, it will be repaired again. This method is only suitable for a large number of general machines.

In recent years, in the era of diversified and real-time big data, it is completely dependent on business experts to diagnose and analyze equipment status, which cannot meet the current pampers diaper machine management needs. Comprehensive evaluation analysis.