Introduction. 1. Capacity and Output. 2. Automation and Control. 3. Material Compatibility. 4. Maintenance and Support. 5. Energy Efficiency. 6. Quality Assuran...

Introduction. 1. Production Capacity. 2. Machine Configuration. 3. Cost and Budget. 4. Machine Reliability. 5. Operator Training and Support. 6. Energy Efficien...

1. Regular Cleaning and Inspection. 2. Lubrication and Maintenance of Moving Parts. 3. Calibration and Performance Testing....

1. Regular Cleaning. 2. Lubrication and Inspection. 3. Preventive Maintenance....

Introduction. Current Market Trends. Key Players in the Industry. Future Prospects....

Introduction. Current Market Size. Key Players and Technological Advancements. Conclusion....

Introduction. Growing Demand for Diaper Manufacturing Machines. Key Market Trends and Opportunities. Conclusion....

Introduction. Growing Demand for Automated Machinery. Technological Advancements and Innovation. Challenges and Opportunities....

Introduction. Machine Setup and Configuration. Operational Parameters and Control. Quality Assurance and Product Inspection. Conclusion....

Introduction. Machine Components and Features. Production Process and Machine Operation. Quality Control and Troubleshooting....

1. Market Demand. 2. Technological Advancements. 3. Market Trends....

1. Increased Production Capacity. 2. Improved Product Quality. 3. Enhanced Customization Options. 4. Cost Efficiency. 5. Sustainability and Eco-Friendliness. 6....

Introduction. Streamlining Production Processes. Proactive Maintenance and Upkeep. Continuous Improvement and Training. Conclusion....

1. Efficient Production Process. 2. Customization and Flexibility. 3. Quality Control and Hygiene Standards....

Introduction. Improved Efficiency and Productivity. Enhanced Quality and Consistency. Cost Savings and Sustainability. Conclusion....

Introduction. Automated Production Line. Continuous Monitoring and Maintenance. Optimized Production Planning. Conclusion....

Introduction. Machine Efficiency and Capacity. Quality and Customization. Automation and Maintenance....

Introduction. 1. Raw Material Selection. 2. Machine Settings and Operation. 3. Quality Control and Testing. Conclusion....

Introduction. Functionality of Infant Diaper Manufacturing Machines. Key Components of Infant Diaper Manufacturing Machines. Maintenance Requirements. Conclusio...

Introduction. Benefits of Efficient Diaper Manufacturing Machines. Maximizing Performance of Diaper Manufacturing Machines. Conclusion....

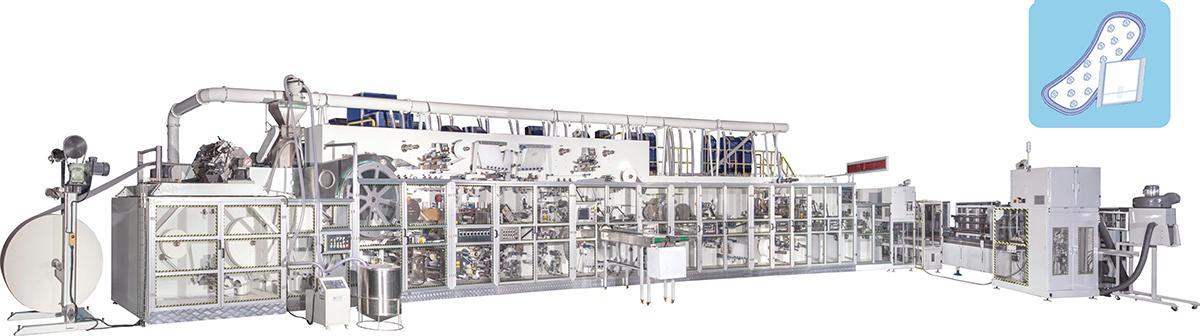

The sanitary napkins making machine is an innovative machine that has transformed the process of making sanitary napkins. The machine has several advantages in terms of its operation. F...

A machine for making sanitary pads is a mechanical device that is used to produce feminine hygiene products. There are several key features that make this product effective and efficien...

Sanitary napkin production line is an efficient and advanced manufacturing system that is designed to produce high-quality sanitary napkins for women. This production line is equipped w...

Adult Diaper Making Machine in India . It is able to produce adult diaper in three sizes, size M/L/XL. Stable working speed 350pcs/min for Msize. Product structure:Legcuff NW., Topshe...

T his is Disposable Underpad Machine in Bahrain. This machine can make 5 sizes, the min. size is 600mm x 600mm and the max size is 900mm x 1200mm . In this machine, we have a special ...

Adult pants machine full servo CLK350 is a production line with a production speed of 350 pieces per minute....

Full automato baby diaper machine precise dosing, high-speed forming, online quality inspection, and intelligent control technologies to ensure consistent product quality, superior sof...