Introduction. 1. Cutting-edge Technology. 2. User-friendly Interface. 3. Quick and Efficient Production. 4. Versatile Functionality. 5. Cost-effective Solution....

Introduction. 1. Automated Raw Material Placement. 2. High-Speed Production. 3. Intelligent Control System. 4. Cutting and Shaping Mechanism. 5. Efficient Absor...

Introduction. 1. Increased Production Efficiency. 2. Customization Options. 3. Quality Control. 4. Cost Savings. 5. Environmental Benefits. 6. Market Expansion....

Introduction. 1. Read the Instruction Manual Carefully. 2. Prepare the Installation Area. 3. Check for Compatibility. 4. Assembly and Installation. 5. Connect t...

Introduction. 1. Production Capacity. 2. Quality Standards. 3. Customization Options. 4. Ease of Operation. 5. Efficiency and Speed. 6. Energy Efficiency. 7. Co...

1. Production Capacity. 2. Machine Reliability. 3. Diaper Quality. 4. Cost-effectiveness. 5. Flexibility and Customization. 6. Technical Support and Training. 7...

1. Capacity and Speed. 2. Customization Options. 3. Energy Efficiency. 4. Maintenance and Support. 5. Quality Control. 6. Hygiene and Safety. 7. Scalability and...

Introduction. Growing Aging Population. Increasing Awareness and Acceptance. Emerging Markets and Technological Advancements. Conclusion....

Regular Cleaning and Lubrication. Inspecting and Replacing Parts. Calibration and Adjustment. ...

Introduction. Improved Comfort and Absorbency. Sustainable Production Practices. Meeting Diverse Needs and Market Demands. Conclusion....

Materials. Design. Production Processes....

Introduction. Optimizing Machine Setup. Improving Workflow and Material Handling. Enhancing Quality Control Measures. Conclusion....

1. Regular Cleaning and Inspection. 2. Lubrication and Belt Tensioning. 3. Preventive Maintenance and Training....

Introduction. Technological Advancements. Eco-Friendliness. Contribution to Global Healthcare....

Introduction. Enhanced Productivity and Efficiency. Improved Quality and Customization. Cost Reduction and Sustainability....

1. Enhanced Efficiency. 2. Cost-Effectiveness. 3. Customization Options....

Streamlined Production Process. Customization and Innovation. Environmental Sustainability....

1. High-Speed Production. 2. Diverse Diaper Styles. 3. Enhanced Diaper Quality....

1. Enhanced Efficiency and Productivity. 2. Customization and Flexibility. 3. Sustainability and Eco-Friendliness....

1. Regular Cleaning. 2. Lubrication. 3. Inspection and Replacement of Parts....

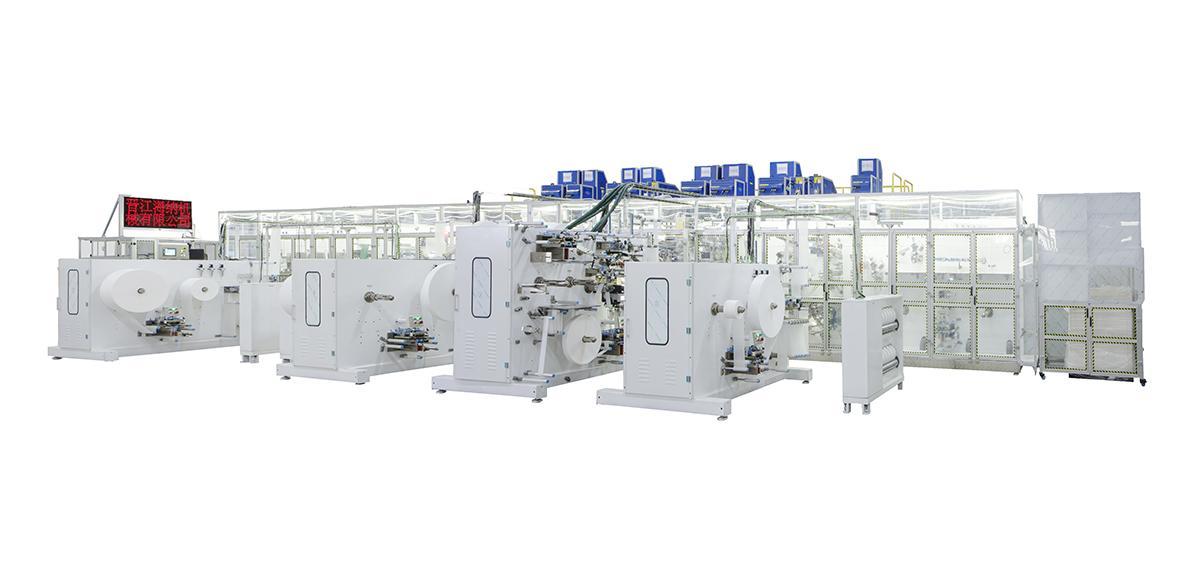

The Pampers making machine is a top-of-the-line piece of equipment designed to efficiently manufacture high-quality diapers. Its advanced features include automatic feeding, cutting, an...

the diaper production machine is an essential tool in the disposable diaper industry. Its automated process, high production capacity, and customizable settings enable manufacturers to ...

The adult diaper machine is a highly efficient and advanced machine designed for the production of high-quality adult diapers. The machine is equipped with cutting-edge technology that ...

This is Underpad Machine for Incontinence in Estonia. The machine stable speed is 250meter/min. The underpad product is a disposable hygiene product, which made up of nonwoven, tissue,...

This is Pull up Baby Diaper Machine in South East Asia. It can produce four sizes of S / M / L / XL, The stable production speed of M size is 500 pieces / min. With the gradual devel...

The design process of fully automatic diaper machine is very complex, mainly because it involves many aspects....

With the improvement of the automation level of modern machinery manufacturing technology, the maintenance requirements of the enterprise's internal infant diaper manufacturing machine ...