Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-09

Through the troubleshooting and maintenance of female diaper making machine faults. Make the maintenance and management work organized, planned, principled, standard and orderly, so as to achieve long service life, high comprehensive efficiency and meet the needs of production development. Make full use of the knowledge of electrical and electronics, sensors, electrical control and production, installation and commissioning, and combine theory with practice, which fully reflects the importance of on-site adaptability of maintenance personnel. At the same time, through the analysis of the subject, the people engaged in the business can be familiar with the equipment faster.

(1) Before maintenance, the power supply and gas source of female diaper making machine should be cut off; when conducting electrical maintenance, the sign of "circuit maintenance, do not power on" should be set to ensure safe operation.

(2) Check first and then check to avoid blindness. When necessary, use drawing data or instrumentation to carry out detection and analysis to determine the fault range.

(3) Adopt correct maintenance methods and methods, correct use of labor, quantity and equipment, orderly disassembly and assembly, pay attention to protect the integrity of female diaper making machinery parts and avoid failure expansion.

(4) After the repair of female diaper making equipment, all the work, quantity, utensils and parts must be collected, cleaned and lubricated, and the test run can be carried out after confirming that it is safe and reliable. After the debugging has reached the performance requirements, it can be put into normal production.

(1) Keep the appearance of female diaper making equipment and the surrounding environment clean, tidy, free of impurities and oil.

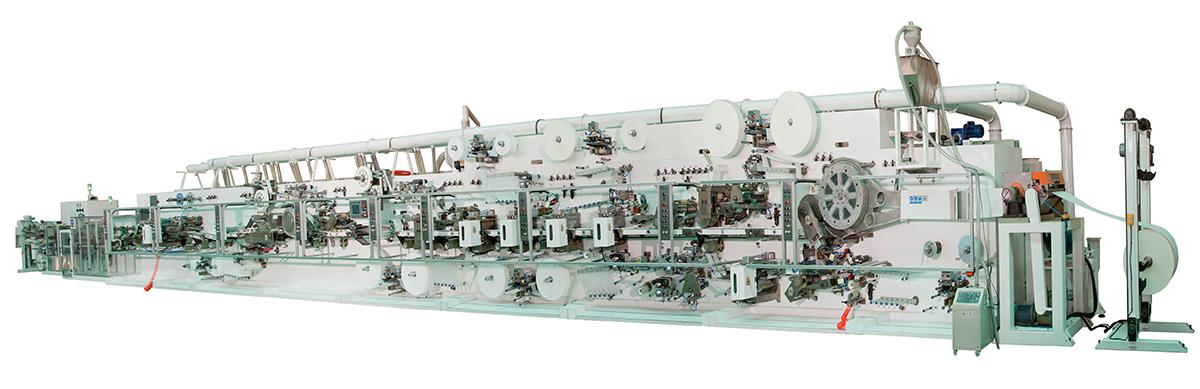

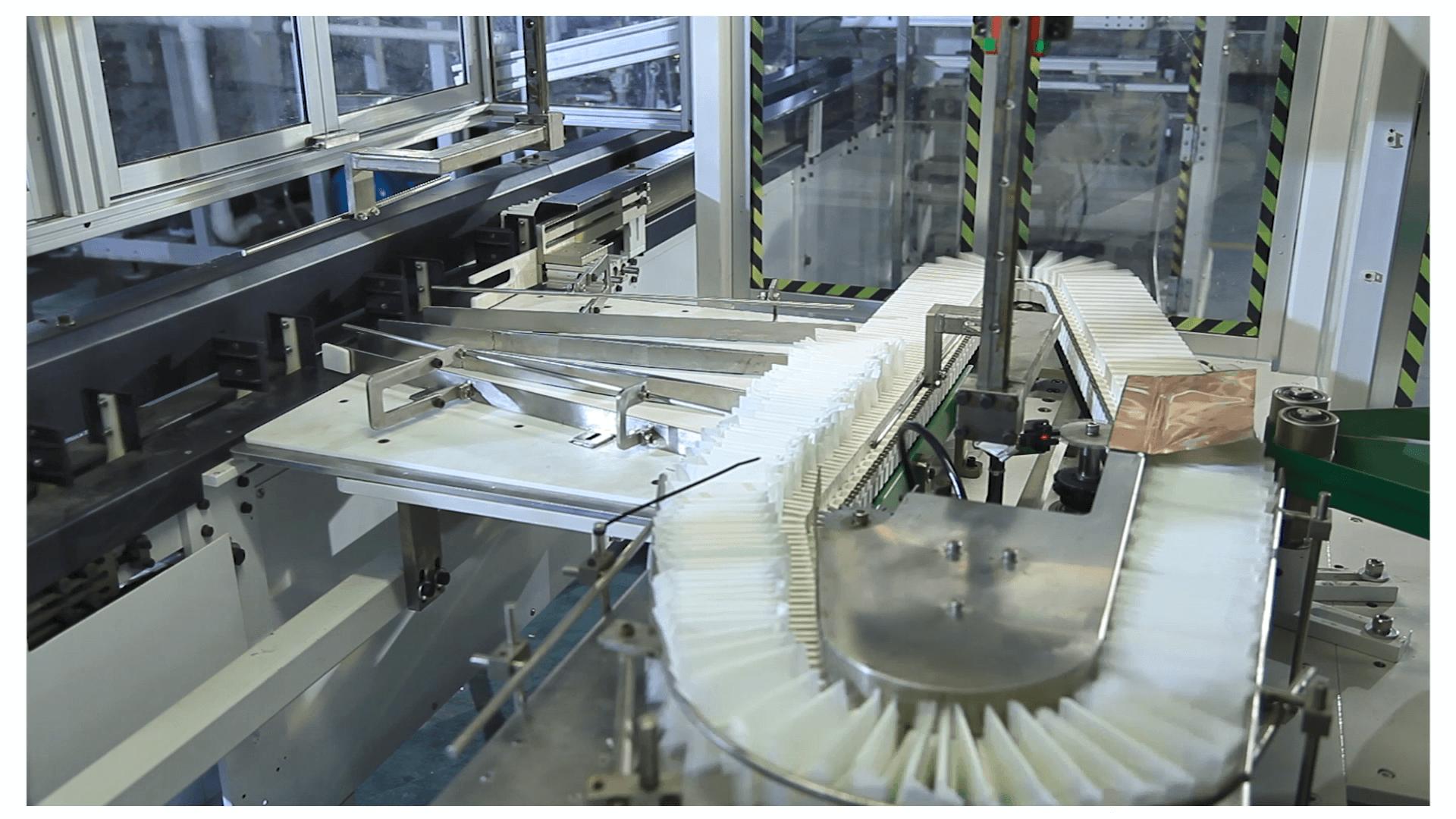

(2) The winding mechanism, vertical folding mechanism, liquid adding mechanism, horizontal folding conveying mechanism, vertical sealing mechanism, horizontal sealing mechanism, transmission mechanism, etc. should be clean and free of sundries.

(3) Always check the matching and tightening state of each cutter and transmission parts; the tightness of chains, belts, and timing belts; and the working state of each pneumatic component. When it is found that it does not meet the requirements, it should be adjusted and repaired in time.

(4) All bearings, gears, chains and gearboxes should be refueled regularly.

(5) All air passages and air-water separation cups should be drained in time to keep the liquid level of the air-water separation cups not exceeding the diverter groove, otherwise the diverted water will enter the air passage.

(6) The electrician of the technical department should regularly inspect the electrical working status: whether the operation buttons, knobs, touch screens, indicator lights, sensors, PLC units, frequency converters, contactors, relays, temperature regulators, heating components, etc. are normal, to ensure that they are in good condition, clean. The electric control cabinet and photoelectric switch should be kept clean, and all kinds of wires should be kept in good contact.

(7) When scrubbing female diaper making machinery rubber parts, plastic parts and paint parts, only water and alcohol are allowed, toluene and natural water are strictly prohibited; organic solvents are prohibited for scrubbing plexiglass.

(8) During operation, the working state of each part should be observed frequently, and if any abnormality occurs, it should be stopped immediately for maintenance.

(1) Before taking up the job, operators should receive fire protection and safety training, be able to identify safety protection signs and be familiar with production safety management methods.

(2) Consciously wear and correctly use labor protective equipment, abide by the operating procedures, carry out safe operations, avoid flukes, and do a good job of preventing noise, scalding, electricity, and mechanical damage.

(3) The protective device should be re-installed in place after maintenance, and should not be disassembled without permission. If it is damaged, it should be replaced in time.

(4) It is strictly forbidden to operate the electrical switch on female diaper making machine when female diaper making machinery is running, handle female diaper making equipment faults or when hands are wet.

(5) If the operation is not in violation of the operating procedures, and there is an abnormality and a precursor to the occurrence of unsafe behavior by the personnel, emergency stop measures should be taken decisively.

(6) Strictly follow the rules and regulations of the company's power distribution department for safe electricity use to ensure that personnel use electricity safely and safely.

To sum up, we should actively protect and maintain according to the actual situation of female diaper making machine.